The U.S. Department of Energy is hoping to secure the future supply of the rare earth elements that are critical to making the nation’s most popular pieces of technology, from hybrid cars to smartphones, tablets and computers.

That’s why the agency on Wednesday announced a $120 million, five-year-grant for a new research center into rare earths. The Critical Materials Institute will be located at Ames National Laboratory in Ames, Iowa, and will be overseen by current Ames director and materials engineering professor Alexander King.

“The supply of the most critical materials is more challenged than any other materials,” King told TPM in a phone interview. “The amount of material demanded today by commercial uses exceeds or threatens to exceed the supply.”

Ames on Wednesday released the following video of King describing the goals of the lab:

The U.S. government in March 2012 filed a trade case against China, the major producer of rare earths for the globe, over export restrictions.

To address the looming shortfall, the new Critical Materials Institute, or “Hub,” as it is known, will focus on developing new ways of leveling the supply-demand ratio of five rare earth elements in particular: neodymium, europium, terbium, dysprosium and yttrium.

In total, there are 17 rare earth elements, but those five “are for which the supply is very close to running out,” King told TPM.

They also happen to be the elements responsible for making such commonplace devices function as light-emitting screens on smartphones and computers, earbuds, car speakers, and hybrid electric car motors.

“You can imagine the shock to world’s teenage population if you suddenly had to replace earbuds with over-the-ear headphones,” King said. “More seriously, the ability to manufacture clean-running automobiles would be severely constrained.”

Even in gas-guzzling autos, rare earths play an important role in the motors that drive power windows and door speakers. A shortage of rare earths would force auto companies to use other materials that would make the doors several inches thicker, decreasing fuel efficiency.

To avoid these scenarios, and to project what materials will be critical to consumer technology in the future in order to manage their supply, the Energy Department is granting the Hub funds for the next five years.

Specifically, King says the new Hub aims to develop ways to improve the efficiency of extracting and isolating rare earth elements, and to quickly transfer this knowledge to mining companies.

“Rare earths are chemically very similar to each other,” King said. “What we need to do is come up with chemicals that can discriminate between rare earths at much higher levels than those used today.”

Currently, it is “very difficult” to separate rare earths from each other and chemically similar elements, King explained. When mining companies look for rare earths in raw ore, they tend to find all 17 together in varying quantities. To isolate specific elements, companies use chemical agents that produce “maybe 5 percent enrichment,” maximum, King said.

The Critical Materials Institute aims to develop chemical agents that produce 20-to-50 percent or greater purification, running software simulations to develop the precise combination of chemicals that can produce higher purification levels.

“That reduces the amount of time, agents and energy used,” King said. “It will also reduce threats to the environment.”

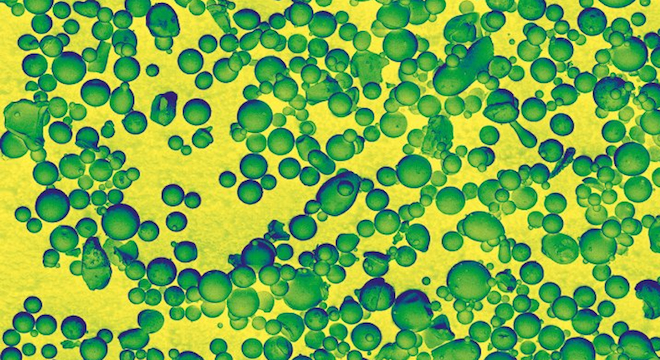

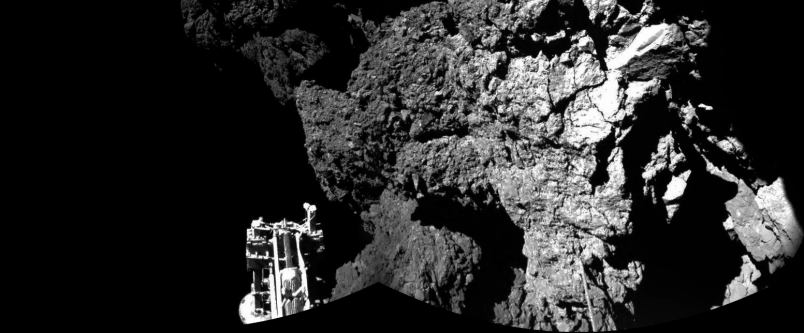

Ames has already been working on other methods to make rare earths into more commercial viable forms, including high-pressure gas atomization and decanting (video demonstrations of both below, via Ames):

The Hub will begin its work in the coming weeks out of existing facilities at Ames and other partner institutes around the country, including a new facility at Idaho National Laboratory. By the end of the five-year-period, upwards of 220 researchers will have worked on projects at the facility, King said. The Energy Department’s funding plan calls for $20 million to be dispensed this year and then $25 million for the subsequent four years.

The Hub is also eligible for federal funding renewal for another 5 years after that, dependent on the advances made during the first funding period. But King said that the researchers weren’t counting entirely on that, and instead hoped to prove their worth to industry partners to for additional funding.

“Our goal is to demonstrate value of work we do, particularly to industry,” King said. “Technology transfer is a very important part of this. If we prove to have value to manufacturing in the U.S., we anticipate well get financial contributions from the manufacturing industry.”

The Critical Materials Institute is the fifth and final such specialized research Hub to be funded by the Energy Department with the goal of producing rapid advances in scientific fields of national interest. The other four Hubs, which were announced previously in 2012, include the Nuclear Reactors Hub, Sunlight Hub, Energy Efficient Buildings Hub and the Batteries Hub. All were modeled after the kind of concentrated, rapid research centers at AT&T’s Bell Laboratories and the Manhattan Project.