Updated 1:58 p.m. EDT, Wednesday, September 26

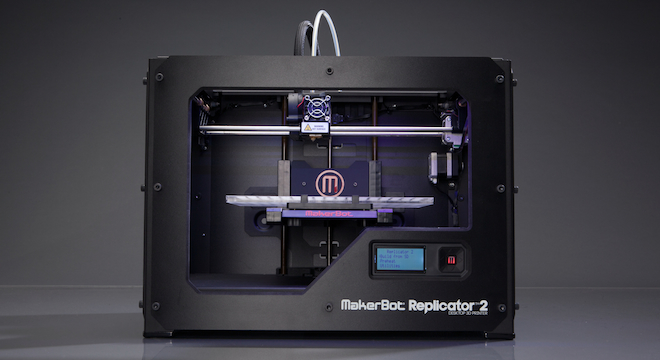

BROOKLYN, NEW YORK — New printers generally don’t warrant their own press conferences, but the Replicator 2 is no ordinary printer.

Unveiled Wednesday in Brooklyn by local startup company MakerBot, the Replicator 2 — available for $2,199 for the lower-end model — is a desktop 3D printer, allowing ambitious users to create their own physical objects out of bioplastic (corn-based PLA) with what’s advertised as considerable ease.

“We’ve defined this as a ‘prosumer’ level device, but this is a great starting point for people who are wanting to jump in to 3D printing,” MakerBot CEO Bre Pettis told TPM at the unveiling event in Brooklyn.

At the same time, Pettis cautioned against the idea of plunking down the over two grand to get a Replicator 2 unless a buyer was ready to devote some serious time and energy to learning the nuances of the activity.

“You could get it if you were just wanting to play around,” Pettis added. “But we specifically made it for the distinguished 3D modeler who has very high expectations of output. So people just getting into it, this is a great machine for them, but we made it so it’s not just a starter machine.”

Pettis’ father Chuck, who works with MarkeBot’s marketing team, said that ideal uses for the new Replicator 2 would be for rapid prototyping and modeling of hardware or other physical products, even buildings.

“[It’s for] if you’re an architect, or you’re doing an internal presentation within your company here’s what we should do on the next car or the next handle or the next iPhone,” the elder Pettis told TPM.

The Replicator 2, actually the young company’s fourth device of its kind, offers considerable improvements over its predecessors, including the original Replicator, which was just unveiled in January.

Altogether, MakerBot, founded in 2009, has in just three yeas sold over 13,000 of its four generations of printer models and as of 2011 had over 20 percent of the entire market share of the nascent industry, according to company documentation.

The Replicator 2 improves over its predecessors in several significant ways that the company hopes will spur even further adoption.

Specifically, the Replicator 2 offers the ability to create objects 37 percent larger than its predecessor, up to 410 cubic inches in volume, or about the size of a, well, conventional computer paper printer.

It also boasts improved resolution, or lower level layers of printed plastic, with a new 100-micron layer (0.0039 inch) resolution setting for those printers who want an especially smooth finish, without the sanding or filing that’s required of other, higher-level layers.

The machine also comes assembled and with a new, easier-to-use software bundle called “Makerware,” that allows users to simply drag and drop 3D models of objects made with basically any of the other popular design and drafting programs already available (AutoCAD and Meshmixer were examples given) into a virtual reproduction of the printer’s build area, and then quickly resize them, clone them or add other objects, all of which can be printed at the same time.

Like previous iterations, it too can print out objects with moving parts already assembled. At the press conference, Pettis and MakerBot staff passed around demo examples of cranks and torque force amplifiers and fully assembled model tractors and a model UPS truck.

The actual speed at which a 3D object is printed depends on the complexity and size of the object itself, but they generally take a few hours each.

MakerBot is also offering a more expensive version for more advanced users called the Replicator 2x, which retails for $600 more.

But it’s the new, first ever MakerBot physical retail store in Manhattan that may be the company’s best chance yet at sprearheading the mainstreaming of the technology, also known as additive manufacturing. The interior is pictured below:

The store, which opened just following the press event, sells not only MakerBot’s Replicator 2 devices, many of which were in the process of printing display objects as the press and random shoppers toured the new space, but also various 3D printed objects: Fully functional watches, 3D printed with all of their moving gears, for $59.99, a family of squirrels of varying size for considerably more than that.

“For a lot of people 3D printing is still science fiction,” Pettis said of the store. “But if you show them what’s possible, then it clicks.”

Late update: Video of the MakerBot Replicator 2 in action at the NoHo store in Manhattan. The bioplastic is printed at 230 degrees Celsius, but cools quickly:

Pettis also told TPM that he was sure that the MakerBot Replicator 2 was capable of printing out the parts necessary to build another Replicator 2, self-replication, as it were.

Correction: This article originally incorrectly identified Bre Pettis’ father by the name “Jacques,” when in fact his name is “Chuck.” We’ve corrected the error in copy and regret it.